Laser technology has been around for a long time, enabling makers to establish new ways for putting together and also tracking their products. From welding plastics to engraving steels, lasers have actually discovered an area in every market. If you are fairly brand-new to this innovation, you are probably questioning what are the distinctions in between laser noting as well as laser inscription– but more importantly, which process is appropriate for you. Laser Processing Methods for Steel.

Laser Processing Methods for Metal

The term laser noting is generally made use of as a word for defining a group of processes. This can vary from a surface noting to a deep engraving, both procedures leave a “mark”. Here are the industry standard terms we utilize for defining the kinds of marking techniques. Ablation. The terms laser engraving and also laser etching are subtypes of this procedure and also are identified by the deepness of the dental caries as well as the means light is mirrored to reveal contrast. Laser inscription is the general term utilized for this approach. Annealing. This is a surface degree alteration of the metal, giving comparison for legibility. Znakowarka do metalu is used to describe this approach in more general terms.

What is Laser Engraving / Ablation?

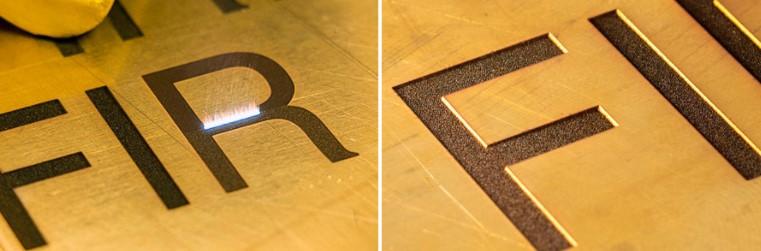

Although these terms are often used interchangeably, there are differences between Znakowarka do metalu , laser engraving and also laser etching. What is Laser Inscription/ Ablation? Laser engraving, or ablation, is a process that includes high laser power with high-speed activity of the laser beam to rapidly vaporize product, revealing an image at eye degree. This develops dental caries in the product that are durable as well as are often done prior to the powder coating procedure. Ablation can additionally be used for eliminating slim layers of material like paint, anodizing, and plastic films. A procedure called laser cleaning is a form of ablation, which is the term utilized for eliminating pollutants like corrosion as well as oil from steel, as well as for cleansing mold and mildews made use of in injection molding. There are two main ablation subtypes called engraving and also etching. Etchings resemble engravings but are identified by elevated sides that reflect light in a different way and also have a much shallower depth. Etching deepness can be 0.02 ″ and up Engraving deepness is normally no more than 0.001 ″. Laser Ablation Instance:. Picosecond laser etched brass. Sample A– Laser inscribed brass using a picosecond fiber laser. Test A was etched utilizing an ultrafast picosecond fiber laser.

What is Laser Marking / Annealing?

The sides are tidy, and also the bordering material was unaffected by the warmth of the laser. This is called the warmth impacted zone (HAZ). We covered this topic in a previous blog post about the unique handling capabilities of ultrafast lasers.

Main Characteristics of Laser Annealing Metal

Here are some instances of engraving/ ablation applications:. Automated Laser Engraving System for Automotive Parts. CO2 Laser Inscription System for Hearing Aids. Eliminating Ink on Laser Markable Paper for Developing UDI Labels. Laser Etching Cliché Plates with Ultrafast Lasers for Pad Printing.

Examples of Laser Marking Applications

What is Laser Marking/ Annealing? Laser marking, or annealing, is the process of changing the surface residential or commercial properties of a product to produce a different mark through an oxidation process. This oxidation is accomplished by gradually warming the material with reduced power to attract the carbon to the surface, creating a readable marking. This process functions well on steel and also most plastics with carbon particles. When annealing, material is not eliminated from the surface area which results in a smooth surface. laser annealed stainless steel appliance panel. Example A.

— Laser annealed stainless-steel making use of a fiber laser. Nevertheless, laser noting non-metals is a different tale as well as isn’t thought about an annealing process. Products like the plastic insulation on wires are marked with the very same localized warmth procedure, causing a rapid noting because of surface area disturbance. This allows us to design high-speed wire noting systems using this carbonization effect. The same can be said concerning noting various other organics like timber and also paper items. Key Qualities of Laser Annealing Metal. Slower procedure than engraving as well as engraving, for the most part. Produces smooth-to-the-touch markings that are lacking of spaces and also crannies that assists protect against corrosion, oxidation, as well as bacterial buildup. Can produce shade variants in stainless steel as well as titanium by changing power degree, pulse frequency, as well as light beam rate. Annealed markings are durable and also simple to tidy. Examples of Laser Marking Applications.

Clinical noting applications that need a distinct device identifier (UDI) to satisfy FDA laws. Noting stainless steel device panels. Marking commercial stainless-steel components. Annealing stainless steel clinical cables. Laser noting plastic light bulb fixtures. Because we’re mainly discussing processing steel,

Which is Right for You?

The sort of procedure depends on the material, desired quality, as well as overall cycle time. Do you require a deep inscribing before a powder layer procedure, or simply a surface level marking? Our applications laboratory has the best range of laser wavelengths and also optics offered for establishing a suitable laser configuration for your process and we enjoy to assist establish an option that works for your product to make sure that you can make a notified decision. Our design division can create completely automated remedies for marking and inscribing applications to reduce laser downtime, human-errors, as well as eventually enhance production throughput. We also have the capacity to mark material while it’s relocating at high speeds with real shut loophole encoder comments. Call us today to begin!